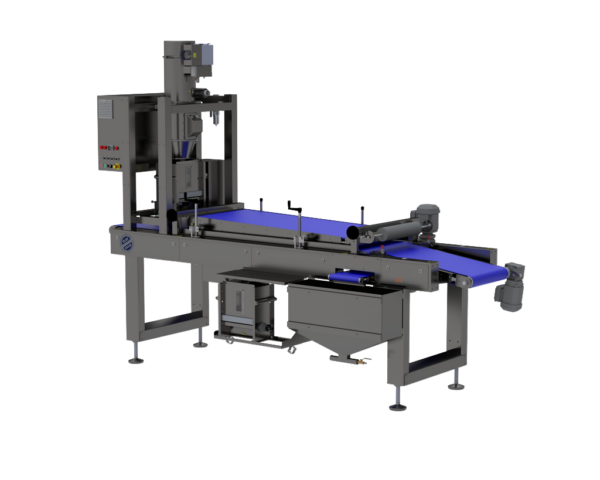

Deco-Seeder η Αυτόματη Μονάδα Σουσαμώματος

Machine to be incorporate in large productions for the seeding of dough pieces max/ 4.200pcs/h depending on dough weight.

Process Description:

After moulding the moulded dough pieces are sprinkled with seeds and rolled in a bed of seeds by means of the extended top moulding belt. A photo eye detects the dough piece and gives the seeding unit an impulse. After a dough bed of seeds is portioned on the belt, seeds are rolled in the dough by a top moulding belt. The non-used seeds are transferred back to the decoration container through a small gap between the decoration- and the discharge belt with the help of a cross conveyor belt and a vacuum system. The decorated dough pieces are transferred straight and discharged to the panner conveyor or any other means of transportation such as a freezer belt or curved conveyor.

Basic execution:

- Stainless steel frame

- Stainless steel undercarriage with 4 fixed feet

- Independent drive

- Synthetic blue belt, width 600 mm

- Decoration belt

- Top moulding belt extended and adjustable in height and speed

- Adjustable Teflon coated side guides, H=20 mm

- Stainless steel curling net

- Adjustable gap for reclaiming access of decoration material

- Cross conveyor to transport non-used decoration material with help of a vacuum pump towards the decoration container

- Discharge conveyor (incl. cleaning position) to transfer the decorated dough pieces into tins. Twister unit can be placed optional on the DecoSeeder

- One exchangeable decoration container, 30 cm, with window for visual control.