The best natural systems to extend the food shelf life, preserving its freshness. Blast chilling immediately stops the moisture in food from evaporating, thereby preventing dehydration. The fragrance and savour of foods is often linked to the right amount of moisture content in food. Tecnomac Black Kube performs the functions of:

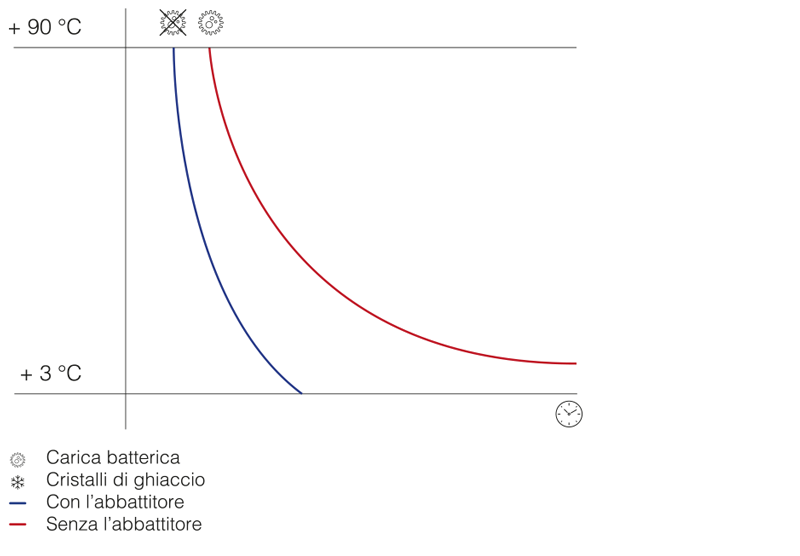

Blast chilling

+90° → +3°C

All food cooked and left to cool slowly loses its finest qualities. Tecnomac blast chillers make it possible to lower the temperature at the core of foods that have just been cooked, down to +3°C. The speed of such process is essential since it allows a reduction in the bacterial proliferation that is particularly critical while food is at temperatures between +65°C and +10°C. The final result is the preservation of the quality, colour and fragrance of food.

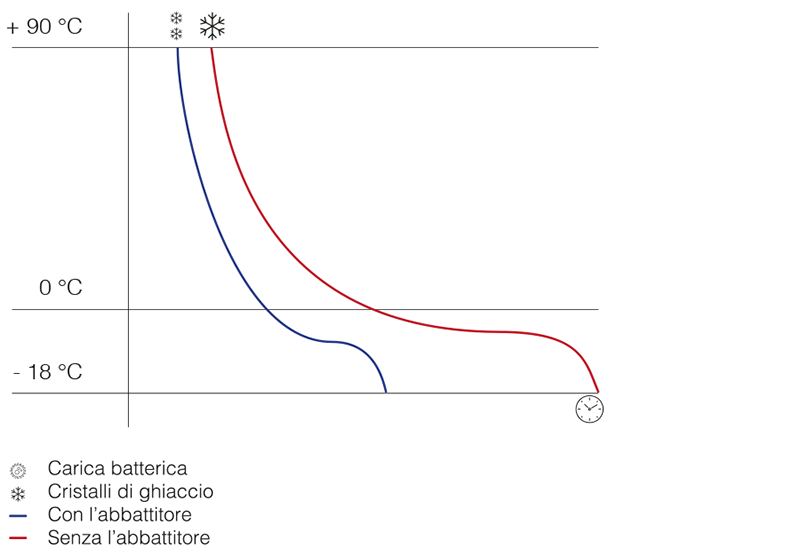

Blast freezing

+90° → -18°C

The blast freezing process is the best process to store food for many months. Tecnomac blast freezers, thanks to their powerful refrigeration system with an air temperature of -40°C, quickly lower the temperature at the core of food to -18°, thus avoiding the macrocrystallization and granting perfect and long-lasting preservation of all the original qualities of the food. After defrosting, there will be no loss of liquid, firmness or savour

Benefits

The daily simplicity at your fingertips

Tecnomac is now introducing the new Black Kube range of blast chillers and blast freezers. These machines are designed to improve the quality and organization of work. Powerful, versatile, easy to use and reliable. These are the most important features of Tecnomac BK+ blast chillers-freezers.

Control Panel

Simple and intuitive soft touch control panel for the optimal visualisation of all the functions.

Cycles

- SOFT:

Suited for delicate or thin foodstuffs such as rice, vegetables, fried food. - HARD:

Very effective for dense, greasy and large-sized foodstuffs. - SHOCK FREEZING:

Suited for any food product

Model Sizes

- BK 3 1/1

Capacity: 3 trays Output chilling:7 kg Output freezing: 5 kg Dimensions: W 600 / D 851 / H 400 Voltage: 230 V – 1N – 50Hz - BK 5 1/1

Capacity: 5 teglie Output chilling: 14 kg Output freezing: 10 kg Dimensions: W 730 / D 660 / H 900 Voltage: 230 V – 1N – 50Hz - BK +10

Capacity: 10 trays Output chilling: 32 kg Output freezing: 22 kg Dimensions: W 800 / D 700 / H 1544: 1599 Voltage: 230 V – 1N – 50Hz - BK +15

Capacity: 15 trays Output chilling: 40 kg Output freezing: 28 kg Dimensions: W 800 / D 800/ H 1950: 2005 Voltage: 400 V – 3N – 50Hz

Description

- Blast chilling / Shock freezing

The most advanced solutions of chilling/freezing for the best product quality and hygiene. - Thawing

Thawing by forced ventilation. - Conservation

Conservation cycles available for any type of product - Ice Cream

The specific function to produce the perfect ice cream.

Technical features

Evaporator

Anti-corrosion resin fan blades.

USB recorder

Data Saving and programs backup.

Ozone Sanification (optional)

Sanitizes the blast chilling chamber after cleaning the machine. Useful also to sanitize working tools

Dual suitability trays rack

Easily removable for cleaning, it is designed to facilitate the chilling air flow, increasing the machine efficiency. Suitable for both GN1/1 and EN 600 x 400 mm trays.

Wheels

Castors kit. (optional).