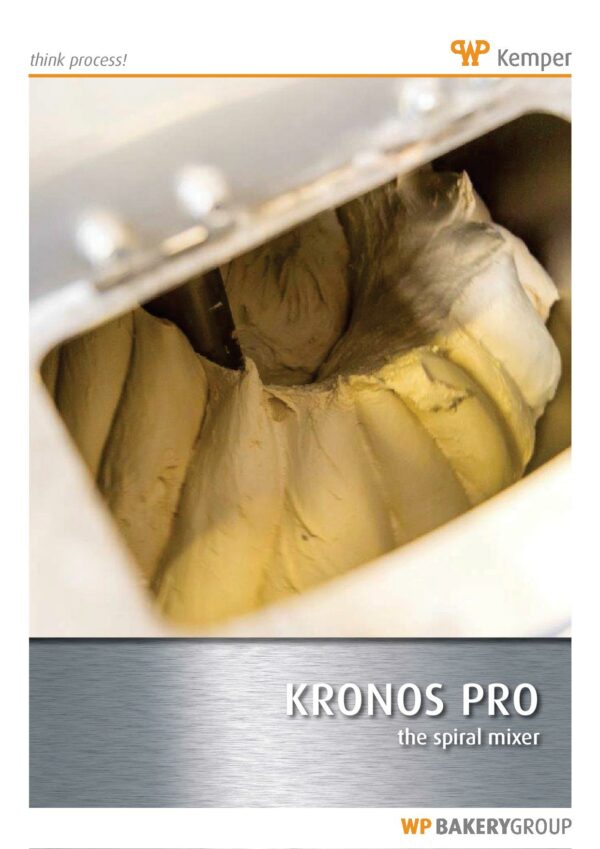

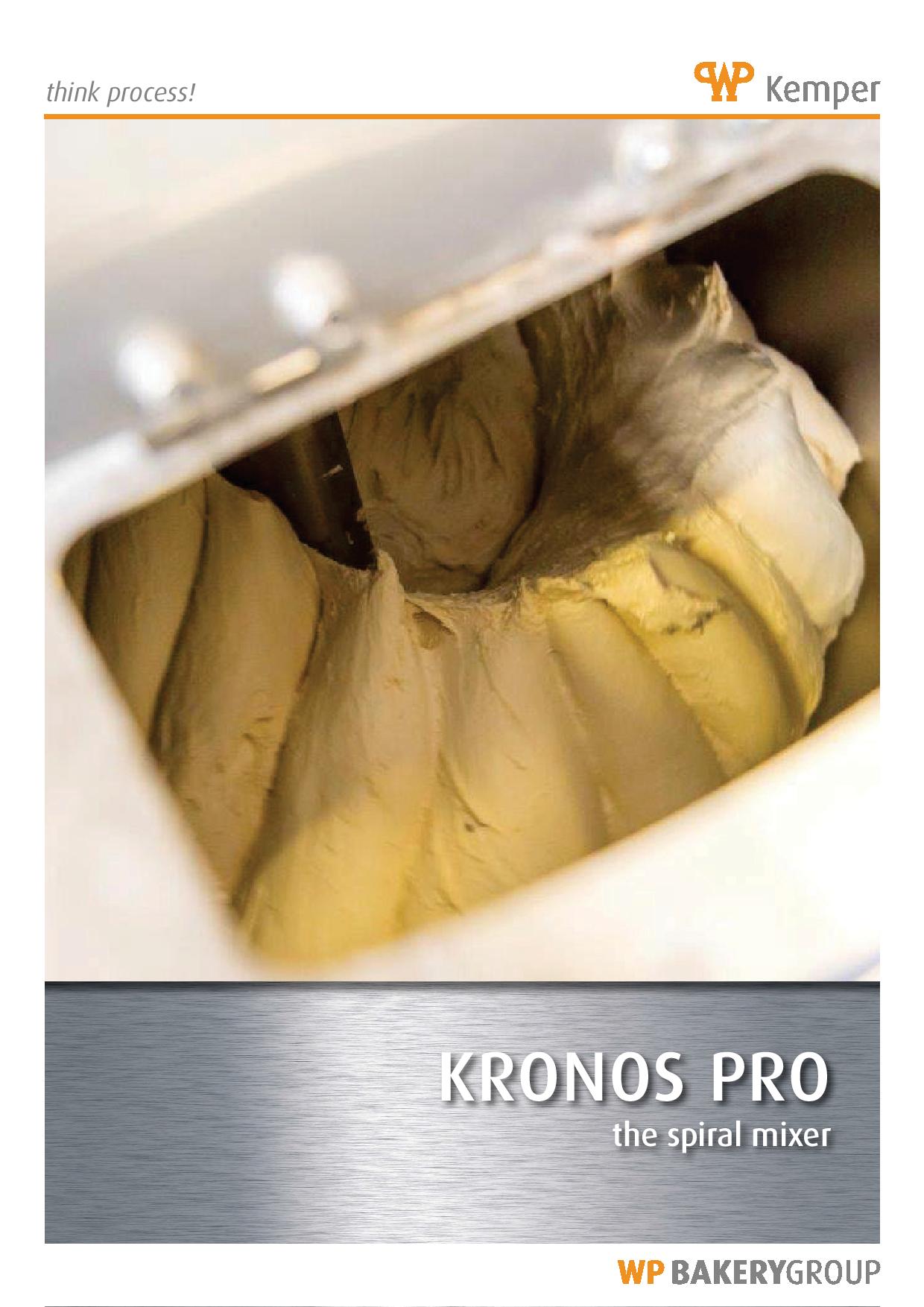

What makes the quality of an optimal dough?

Good raw materials are essential for good doughs as the quality of water and flour significantly influences the dough quality. In addition to the raw materials, optimal mixing ensures the best product quality. Each dough has different requirements, soft doughs require a lot of tension and volume, rye doughs have to be mixed gently. Mixing tools matched to the type of dough increase the quality of the dough.

High dough quality through sophisticated technology

When it comes to dough quality, there is nobody out there who knows the business better than us. Our systems are second to none, both in traditional dough processing relying on stand-alone universal mixers or single batch equipment, and in industrial dough processing with fully automated mixing systems precisely customized to specific production conditions. Our 3-zone mixing principle always ensures optimally mixed doughs.

Oxygen-content

To ensure a strong formation of the gluten network and a dry dough surface, a lot of oxygen has to be added during the mixing process.

Gluten network

An optimally developed gluten network ensures high dough quality and thus also a high baked goods quality.

Water absorption

A short start-up phase allows for quick blending of ingredients. Thus, water is bound before formation of the gluten networks. This ensures a longer freshness and more flavor in the final product.

Features

- Reproducible doughs

- Easy maintenance

- Short delivery times

- Compatible bowls with President & Titan mixers

Products

- Wheat dough

- Mixed-wheat dough

- Mixed rye dough

- Rye dough

Capacity

- Flour 75 – 150 kg (165 – 330 lb)

- Dough 120 – 240 kg (265 – 530 lb)

- Models available : 120, 160, 200, 240, 400